Laboratorio Fly-By-Wire

The activities carried out in the Fly-By-Wire Laboratory essentially deal with the theretical and experimental study of onboard systems and equipments, with special focus on:

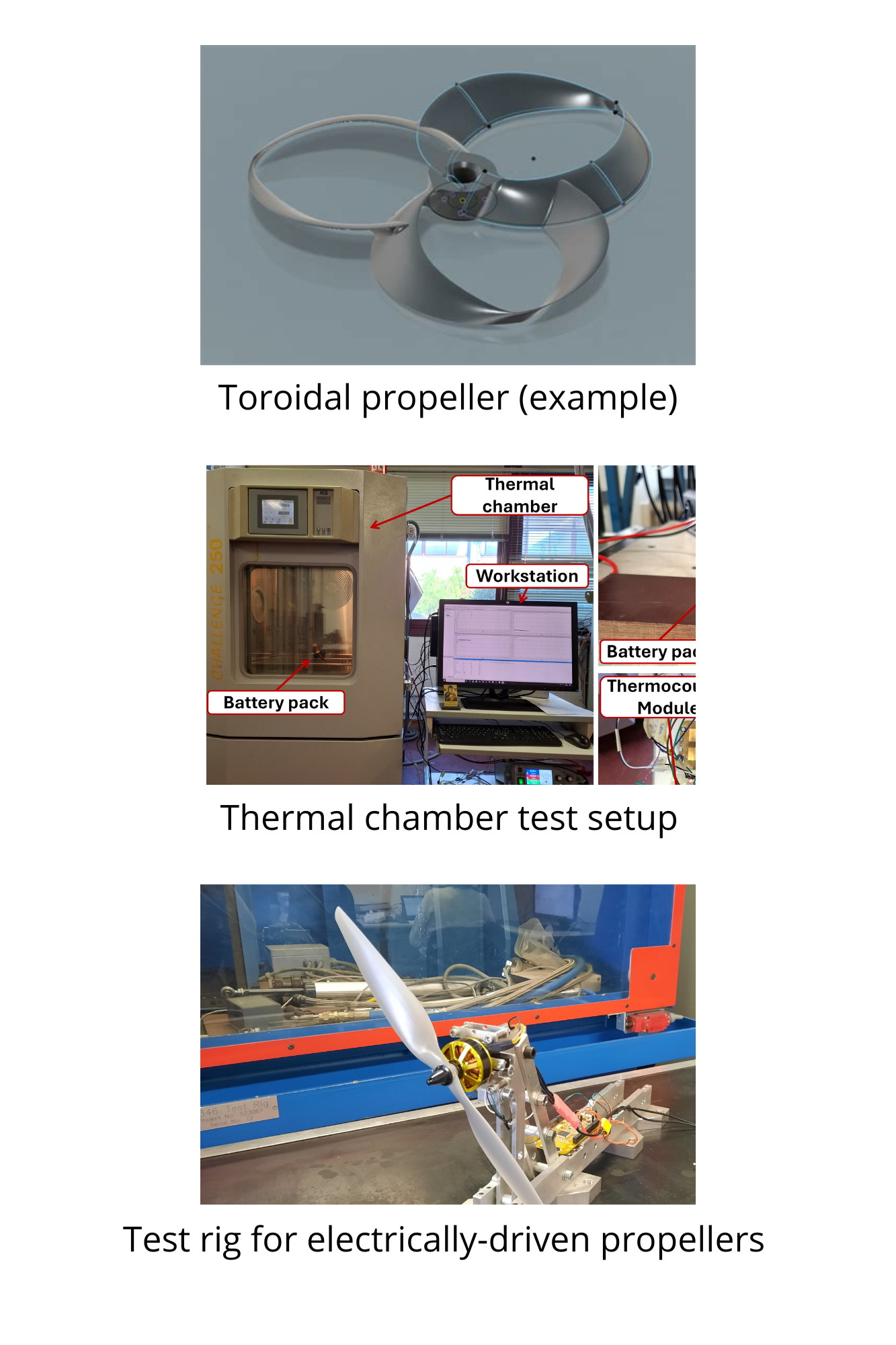

- Safety-critical mechatronic systems (flight control actuators, electric motors for aeronautical propulsion)

- Lithium-Ion batteries for UAV applications

- Thrust and lift propellers for UAV applications

The studies are conducted by integrating

- Dynamic modelling/simulation

- Stability assessment and perfomance analysis

- Fault simulations

- Control design and health-monitoring

- Controllability and observability

- Development of health-monitoring algorithms

- Development of finite-state-machines for failure management

- Implementation of control SW on microcontrollers

- Experimental characterization of performances

- Commands tracking and disturbance rejection

- Performance sensitivity to temperature and humidity

- Real-Time Model-/Processor-/Hardware-In-The-Loop (MIL, PIL, HIL) simulations

To conduct the above-mentioned studies, the following facilities are available:

Test rig for electric motors (max 2 kW) and propellers (max diameter 40 cm)

3D resin printer (Elegoo Jupiter SE)

- Net volume: 275 x 150 x 300 mm³

- Screen: 12,8'', LCD 6K

- Resolution: 51um

Climatic chamber (Angelantoni Challenge 250C)

- Net volume: 224 litri

- Operative range of temperature (empty): from -60 °C to +180 °C

- Operative range of relative humidity (empty): from 10 % to 98 %

- Max temperature rate (empty): +/-5 °C/min

- Power draw: max 9 kW ; mean 5.7 kW

Le attività condotte nel Laboratorio Fly-By-Wire riguardano essenzialmente lo studio teorico e sperimentale di impianti e sistemi imbarcati su velivoli, con particolare riferimento a:

- Sistemi meccatronici safety-critical (attuazione comandi di volo, motori elettrici di propulsione)

- Batterie a ioni di litio per applicazioni UAV

- Eliche di spinta e di sostentamento per applicazioni UAV

Gli studi condotti prevedono un'articolazione organica di attività come

- Modellazione/simulazione dinamica

- Stabilità e analisi prestazioni

- Simulazione guasti

- Sviluppo leggi di controllo

- Controllabilità e osservabilità

- Sviluppo algoritmi di monitoraggio

- Sviluppo macchine a stati per gestione avarie

- Implementazione di SW di controllo su microcontrollori

- Sviluppo algoritmi di monitoraggio

- Test di caratterizzazione prestazioni

- Tracciamento comandi e reiezione disturbi

- Sensibilità prestazioni a temperatura e umidità

- Simulazioni Real-Time Model-/Processor-/Hardware-In-The-Loop (MIL, PIL, HIL)

Per lo svolgimento delle attività, presso il Laboratorio FLy-By-Wire sono disponibili le seguenti attrezzature:

Banco prova per motori elettrici (max 2 kW) ed eliche (diametro max 40 cm)

Stampante 3D a resina (Elegoo Jupiter SE)

- Volume utile: 275 x 150 x 300 mm³

- Schermo: 12,8'', LCD 6K

- Risoluzione: 51um

Camera climatica (Angelantoni Challenge 250C)

- Volume utile: 224 litri

- Intervallo operativo di temperatura (a vuoto): da -60 °C a +180 °C

- Intervallo operativo di umidità relativa (a vuoto): da 10 % a 98 %

- Rateo massimo di temperatura (a vuoto): +/-5 °C/min

- Potenza assorbita: max 9 kW ; media 5.7 kW